Johnsonite Vinyl Base Operation Maintenance Instructions

2 repeated on heavily soiled floors prepare a cleaning solution using one of the recommended ph neutral cleaners maintenance product reference chart below.

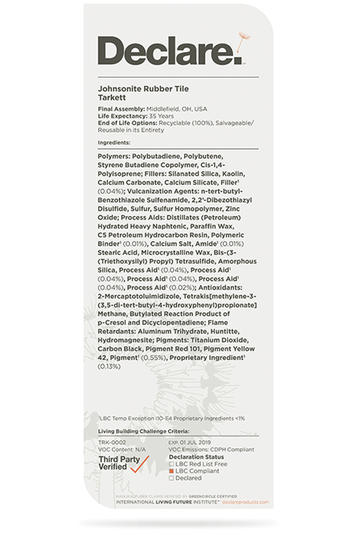

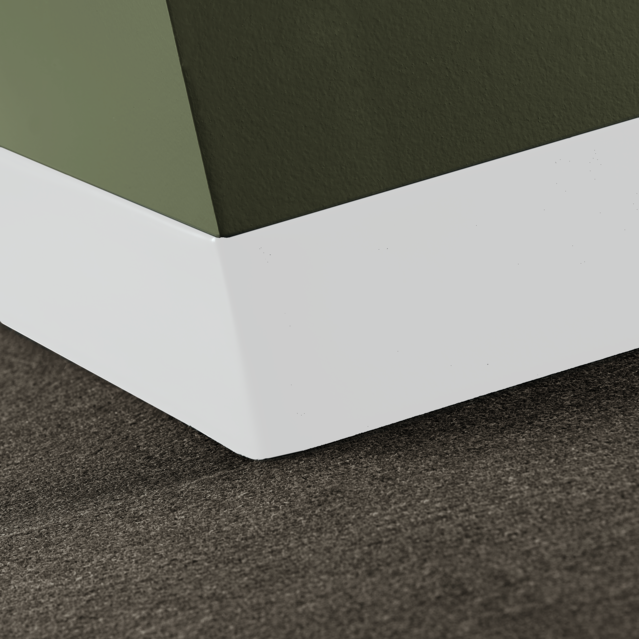

Johnsonite vinyl base operation maintenance instructions. Care must be taken not to pull the wall base excessively when removing it from the carton or unrolling the coils. When butting wall base seams together it may be necessary to square cut the factory edge if butt ends do not align. A regular maintenance program must be started after the initial cleaning. Coarse scrubbing media or harsh cleaning chemicals may damage the surface of the wall base.

The dilution ratio depends on light to heavy soil conditions. Balanced solutions for productive spaces. 1 8 x 1 8 x 1 8 square notched trowel. Rubber wall base astm e 648 nfpa 253.

As part of the tarkett family johnsonite has delivered the broadest portfolio of high performance resilient flooring surfaces in the industry. An acrylic wax may be applied to increase the gloss level when desired. Coarse scrubbing media or harsh cleaning chemicals may damage the surface of the wall base. Johnsonite resilient wall base is maintained with regular wiping using a wet clean soft white cloth.

A mild detergent may be added to the water. See johnsonite wall base installation instructions for complete details. Thoroughly sweep or vacuum the flooring to remove all loose dirt and grit. Room temperature must be between 65 and 75 f 18 and 22 c.

A mild soap may be added to the water. Johnsonite power tape and rubber or vinyl stair treads must be site conditioned at room temperature for 24 hours prior to during and after the installation. Coarse scrubbing media or harsh cleaning chemicals may damage the surface of the wall base. A regular maintenance program must be started after the initial cleaning.

The wall base and adhesives shall be conditioned in the same manner. Critical radiant flux class i astm e 84 nfpa 255 flame smoke class c 450 3. With practical solutions and healthier materials that support every stage of the project from specification to installation to maintenance we re able to deliver measurable return on investment and. Areas to receive wall base shall be clean fully enclosed weathertight and maintained at a uniform temperature of at least 650 f for 24 hours before during and after the installation is completed.

Tarkett 960 cove base adhesive porous surfaces. Cut the johnsonite millwork resilient wall base to the required lengths using a standard or sliding compound miter saw equipped with a carbide tip blade with 80 teeth or greater. Johnsonite rubber and vinyl wall base are maintained with regular wiping with a soft wet cloth. Johnsonite resilient wall base is maintained with regular wiping using a wet clean soft white cloth.