Kanban Container Size Formula

The container size quantity chose was exactly the average demand plus th e scrap factor calculated before.

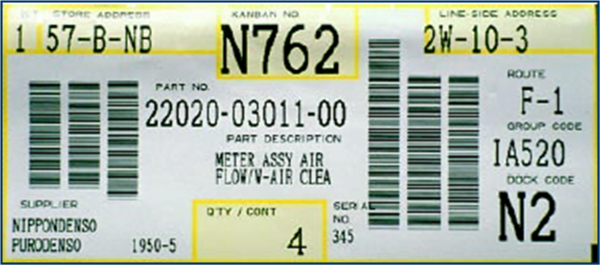

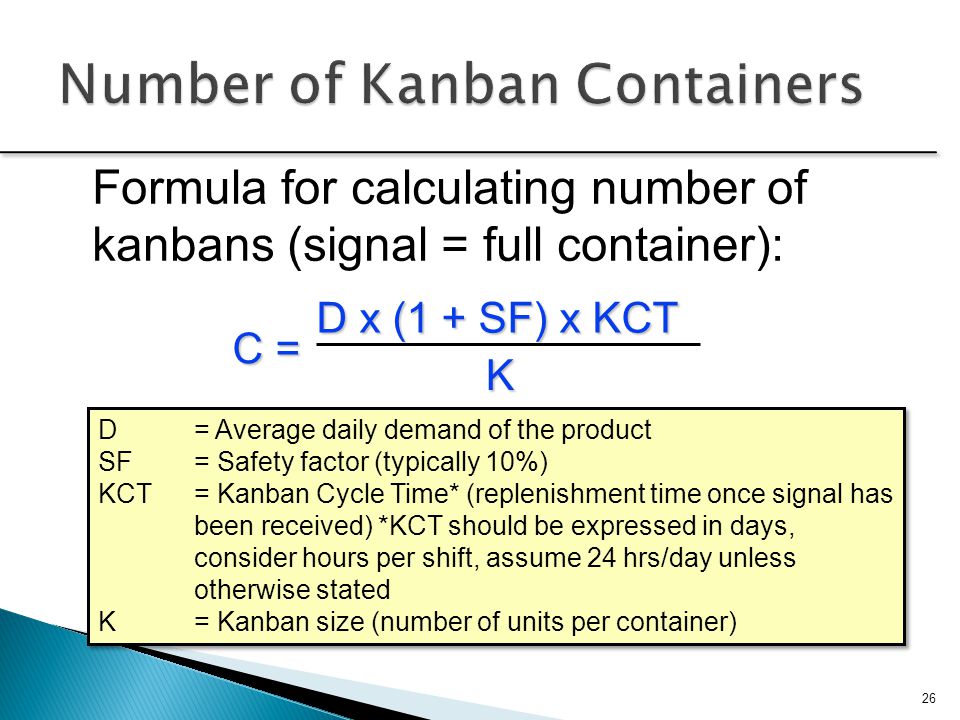

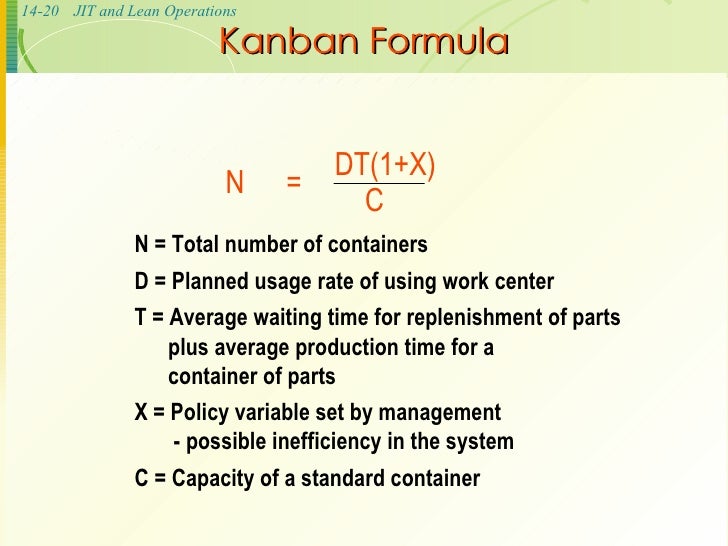

Kanban container size formula. Kanban size number of kanban ad rt sf sd scq ad. N of kanban 100 5 1 20 50 12 kanban what does it means. Dissertations and theses spring 2012 determining kanban size using mathematical programming and discrete event simulation for a manufacturing system with large production variability abigail michele gaston embry riddle. Kanban ad rt sf sd scq.

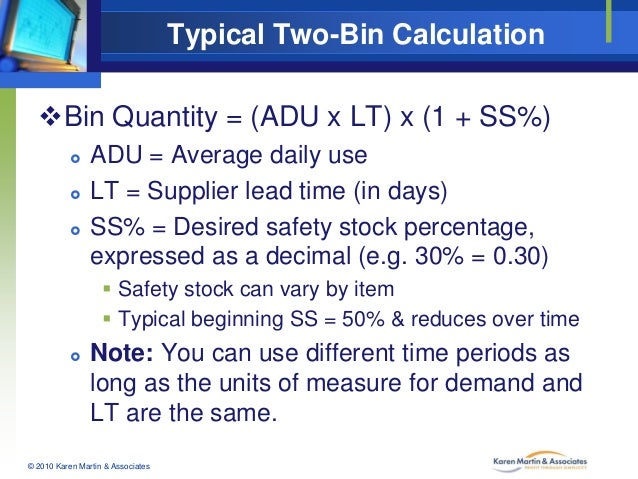

Total required inventory tri average period demand replenishment time 1 x where x 20 40 and the of bins tri container or bin size 5. The kanban calculation is nothing more than a very rough estimate using many assumptions. Normaly it will be sent in form of a kanban card card kanban or. Value a 75.

Total required inventory tri weekly part usage supplier lead time total locations for stock kanban tri container capacity. Compute the weekly usage 3900 52 weeks 75 widgets per week. Total required inventory tri weekly part usage lead time number of locations for stock kanban tri bin capacity a part of just in time manufacturing toyota s taichi ohno introduced kanban as a tool. I t is not precise.

Kanban formula kanban calculation it sounds like physics or science it all sounds so precise. But let me be very clear on one point. Every container is of 50 tapes. Buffer or safety factor number of kanban dd lt ss kbs 1 dd.

The container size standardisation was the key to make the kanban quantities sta ndard.